3

|

|

| |

There is a very comprehensive FAQ on the web, but my

personal opinion is that it's not quite complete and up-to-date.

Therefore I've put in my own little FAQ to spice up the old one. If you

have any questions that are not answered by the original FAQ, then send

me a message and I'll see what I can do. |

|

Setting up the Tonearm

section |

| There are three things that have to be adjusted before

you start using your Technics turntable: the balance arm (=stylus

pressure), anti-skating and the tonearm height. When I first used mine I

didn't really see the importance of precise adjustment, but as soon as

you progress you will definitaly notice the difference. Especially if

you're into scratching records these things are a must to adjust!

Adjusting the balance and setting the stylus pressure:

- Make sure the balance weight is on right and take the arm out of

the safety catch.

- Hold the arm on your finger and turn the weight until the arm is

balanced horizontal.

- Now refasten the arm and set the stylus pressure ring (it's the

one mounted on the weight) to zero (align the zero with the groove on

the tonearm).

- Turn the balance weight clockwise until the pressure ring is at

the desired amount (follow the cartridge manufacturer's

recommendation).

I use a ORTOFON Concorde PRO which has a stylus pressure range of

3.0-5.0 grams and the manufacturer advises to use 4 grams. I therefore

would turn the balance until it made one full rotation which is exactly

4 grams.

Adjusting the anti-skating control:

Set the anti-skating ring to the same value as the stylus pressure. If

you have used a pressure higher than 3 then you should turn the ring to

its maximum value of 3.

Adjusting the tonearm height:

You can set the tonearm height up to 6mm high. Use the following table

to figure out how high you need to put it:

| Height of

cartridge (mm) |

Scale on

height adjust ring |

| 15 |

0 |

| 16 |

1 |

| 17 |

2 |

| 18 |

3 |

| 19 |

4 |

| 20 |

5 |

| 21 |

6 |

The height of the cartridge is measured from the tip of the diamond

to the roof of the stylus. My Concorde PRO for example is about 29mm

high and therefore I just put my height adjust ring on 6. Remember to

lock the ring after you're done adjusting the tonearm height. |

|

Isolating your turntables

from vibrations |

| The 1200 and the 1210 are made to withstand heavy

vibrations caused by high decibels. The sound dampening construction (as

described earlier) make these turntables probably the most solid

turntables in the industry, but in environments with very high sound

vibrations there is always the danger of rumble. This rumble can be

compared with the "scream" of a microphone when held close to a speaker.

What happens with the microphone is that the sound it amplifies

travels through the speakers back into the microphone therefore creating

a loop. The turntables have a similar problem amplifying the grooves in

a record and picking up the tremendous vibrations (i.e. bass and people

dancing) through the surface they are put on which then creates a loop

resulting in a low rumbling sound.

This problem is most common in clubs and at raves where sound levels

get close to 120dB (115dB is the usual limit). There are many ways of

eliminating this rumble. They include simple rubber bands or bungy-cords

and big investments like building a shaft all the way down to the

foundation of the building. It all comes down to eliminating direct

contact between the turntables and the vibrations.

Here's how I do it: take a long rectangular box (made from any

material you like) on which at least two turntables can be placed and

with at least a 3in. depth. The box has to have an open top so you can

fill it up with sand. The sand should be of fine grain and also make

sure it is clean (don't go to the beach, buy it at a shop). Then all you

have to do is put a sheet of fabric over the top so it looks good and no

sand gets into your equipment. Place your tables firmly on top and your

all set!

It's very cheap and very efficient. Just make sure the turntables are on

the sand and not on the box, because the sand will absorb ALL

vibrations. It speaks for itself that this is for permanent systems and

not for mobile systems! |

|

Getting rid of the

static buzz |

| One of the things that many beginning DJ's are troubled

with is the 'static' buzz that you hear during play and the cracking

sound when touching parts of the turntable. This is because the

turntable is not adequately grounded. The actual "hum" sound comes from

the power source.

If your turntable has a cable with ground than make sure you plug it

into an outlet that's grounded. This will not only help eliminate the

buzz a little bit, but it will also keep the electronics inside the

turntable from frying when there is a shortcut.

Although this helps a bit, you should also make sure you hook up the two

little cables that come out of the turntable (the ones besides the power

cable and the RCA plugs, or Cinch-cables as they are called in Europe)

to something that is grounded by contact. The best thing to do is to

attach them to your mixer or amplifier by unscrewing a random screw on

the console and to tighten the two cables underneath it.

Because the mixer is usually grounded itself and because it is grounded

by you touching it all the time, the buzz generated by your SL1200 or

SL1210 will be eliminated! |

|

Opening the top

|

This is just a little section on how to remove the

platter from the turntable. I noticed that many people enjoy opening

them often and this without any care for the magnet. The magnet is what

drives the platter and it is quite a strong one, that's why the SL1200

is so good! Here's what to do:

- If you want to be absolutely sure nothing goes wrong during this

procedure you should unplug the power supply of the turntable. This is

to ensure you don't accidentally turn it on after you took off the

platter as this will result in a blowout of the motor.

- Remove the slipmat and put each of your index fingers in the two

holes in the platter

- Jerk the platter off the spindle in a strait up move and with

equal force on both fingers. Since the magnet is so strong it can help

you damage the spindle, maybe even bending it a little, so be

cautious!

- Now you can grab a Philips screwdriver and take those five screws

around the plastic cover out.

- Here comes the most important part. When putting the platter back

on the spindle DON'T DROP IT, very slowly lower it down or else you

could damage the magnet which is under the platter.

Keep this procedure in mind whenever opening the top of your

SL1200/1210mkII. |

|

Adjusting the pitch

amount |

| In this section you will finally know what those "pitch

circles" are on the side of the platter! Before you start opening your

SL1200, make sure you know how to properly open the tuntable by reading

the section above. If you just noticed how dirty your turntable is on

the inside while opening it, then

clean it. Now we can go on to adjusting the pitch and this is where

the neat pitch speed graph comes in handy. It is marked next to the

power button and this is what it represents:

| o |

+6% |

Top layer of circles is standing still; the speed of the

platter is 6% above the zero position |

| o |

+3.3% |

Second layer is still; the platter is spinning 3.3%

faster |

| O |

0% |

The biggest circles are still. If your pitch slider is in

the zero position right now, then you're ok. If you notice the

circles standing still in two different spots on the slider then

you're not ok |

| o |

-3.3% |

Bottom layer is still |

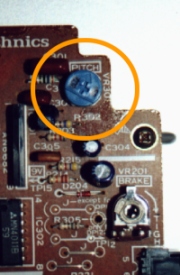

All the way in the top right corner of

the circuit board is a blue plastic switch which has the label "PITCH",

this is pot VR301. (marked on the right) By turning this one in

different directions you will adjust the speed. All the way in the top right corner of

the circuit board is a blue plastic switch which has the label "PITCH",

this is pot VR301. (marked on the right) By turning this one in

different directions you will adjust the speed.

For maximum speed turn the pot all the way clockwise and for minimum

speed turn it counter clockwise. Remember that you will loose precision

with the pitch control when doing this!

For the big picture

click here.

(148Kb)

To adjust it so that it actually turns at +6%, +3.3%, 0% or -3.3%

when that's where the pitch control slider is (calibration) then I

recommend the following procedure:

- First open the turntable as described above.

- Put the platter back on WITHOUT replacing the plastic cover

underneath it. This will make the rest very easy and a lot faster.

- Now you should be able to reach the VR301 pot with a screwdriver

through one of the two holes in the platter.

- Put the pitch control slider at +3.3% and press play.

- You can now determine whether it's going too fast or too slow by

looking at the circles on the side of the platter..

- Press stop and increase the amount of pitch if it was going too

slow or visa versa.

Repeat this procedure until you've got it at the speed you like and

try to get it as close as it can get to all of +6%,+3.3%,0% and -3.3%.

Don't worry if you have to compromise, I never managed to get all of

them right at the same time on mine.

Some people ask me if fiddling around with the pitch can harm the

turntable. My opinion is that it doesn't as long as you don't do it a

hundred times a day. When you just bought your turntable(s) it's

probably best not to adjust the pitch unless you really want that extra

speed. There are two reasons for this:

- It will be a lot harder to make accurate pitch adjustments (with

the fader) while mixing when the pitch is pushed to 12%!

- Once you changed the pitch from it's original factory settings it

is hard to get the pitch exactly back to those settings.

So think twice before you adjust the pitch! |

|

Adjusting the brake

amount |

| This one is easy if you managed adjusting the pitch

amount in the section above. Read "Opening the top"

if you have never opened the turntable before!

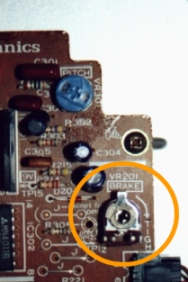

Also in the top right

corner of the circuit board is a (metal) switch labeled "BRAKE" and this

is pot VR201. It even shows which way to turn it to make it tighter. Also in the top right

corner of the circuit board is a (metal) switch labeled "BRAKE" and this

is pot VR201. It even shows which way to turn it to make it tighter.

For the big picture

click here.

(148Kb)

I recommend following the same procedure as above with only a few

extra details:

- Set your turntable up as described in sections 1 to 3.

- This time you should put a slipmat and a record on the platter too

when testing the brake amount, because it is affected by their weight

and by the friction of the needle on the record.

- Put the needle on the record and press play. Let it fully get up

to speed and then press stop to see how it brakes.

- Take of the needle, record and slipmat and adjust the brake to

your liking. Making it tighter (turn the pot clockwise) will make it

stop quicker and visa versa.

You can make the record slowly turn to a halt, make it stop on the

spot or even make it spin backwards when you press stop. |

|

Turntable

calibration |

When you have two turntables and are seriously into

mixing then calibrating them is a very handy thing. You don't want one

turntable to turn at regular speed when the other one has a faster

pitch, because it is annoying when mixing. If for example one of them is

running on maximum pitch, then you want to adjust the pitch of the other

one so that it too runs at maximum capacity.

Just follow the guidelines in "Adjusting the pitch

amount" and make sure their pitches are calibrated.

|